Number of misguided motorists that avoid servicing over cost fears is “alarming”

Half of UK drivers worry about unexpected car bills, survey finds

Millions of motorists are avoiding car maintenance over fears of unexpected problems, with many admitting that they avoid getting their car serviced in case vehicle faults are found.

Around half of UK drivers (47 per cent) worry about having to pay for unexpected car repairs.

The survey of 2,000 motorists also found that a quarter (24 per cent) of those who worry about unexpected problems say this uncertainty is putting them off getting their car serviced.

The research suggests that drivers are paying hundreds of pounds to pass an MOT, with five per cent paying £1,000 or more to get their vehicle through the test.

Further MOT analysis reveals that around 40 per cent of cars fail their MOT at the first attempt.

Lauren French, product manager at RAC MOT Assist, the company behind the research, said: “Clearly, taking a car in for a service or MOT can be a nerve-wracking experience with many drivers concerned about what might be uncovered, and the unpleasant financial consequences that can result.

“But it’s even more alarming that this experience is enough to put some people off getting their car serviced in the future.

“Just how many people are driving vehicles on the UK’s roads that they know have problems?

“The best advice to any driver is to keep on top of servicing and maintenance work – the quicker problems are identified, often the cheaper they are to remedy.”

“Spread your Servicing and MOT costs.”

Here at Aarons Autos we advise our customers to spread their servicing and MOT if cost is an issue, this way they can plan for the up-coming months.

If the car has any advisories on the MOT they can save money and have those carried out with a ‘Service’ six months later, and also if we find anything on the service they can save and have the work done when there MOT is due.

Your friendly car garage in Derby

Give us a call at Aarons Autos for more info.

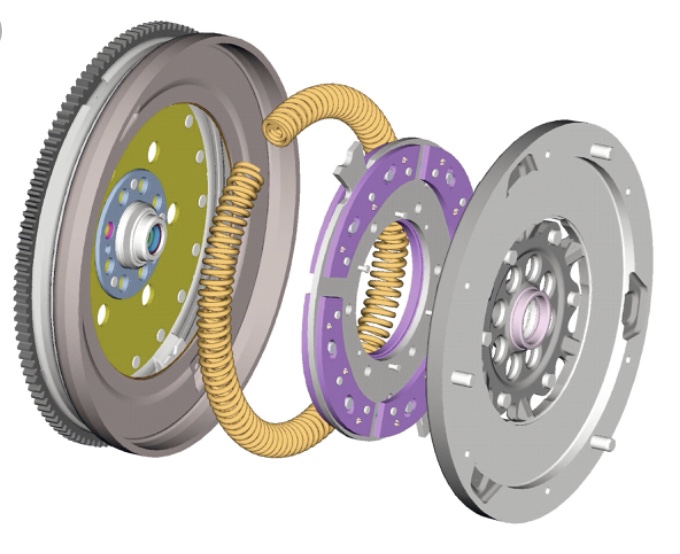

However, with all moving parts, especially ones under stress they wear causing noises, vibrations and lastly drive line failure!

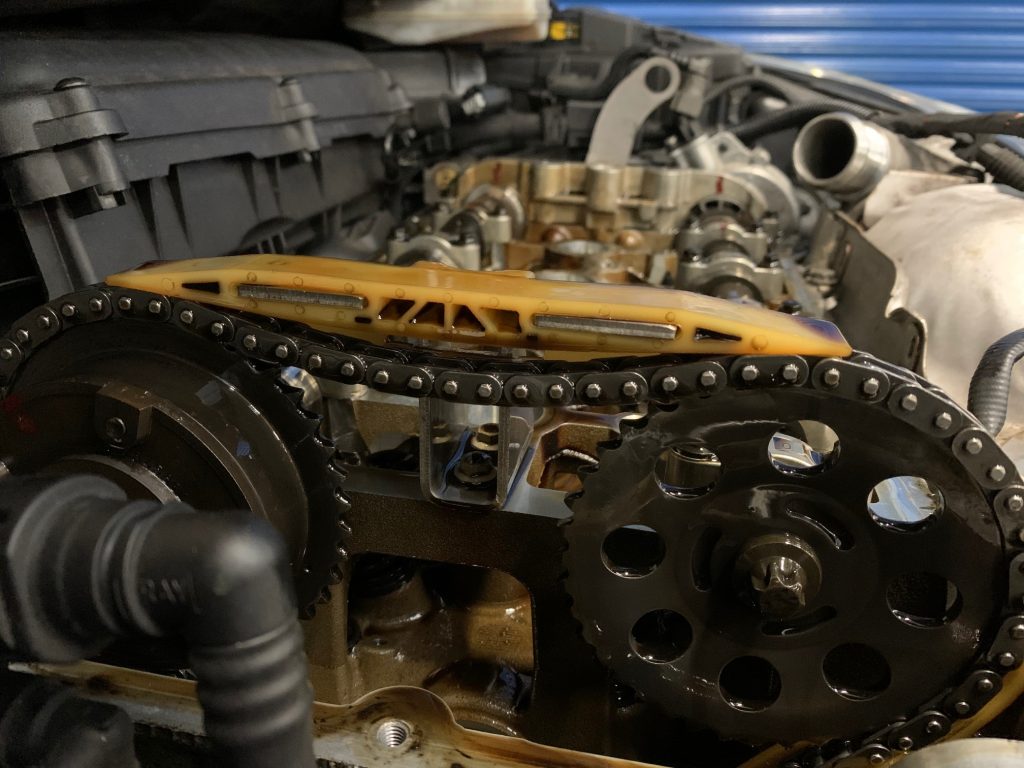

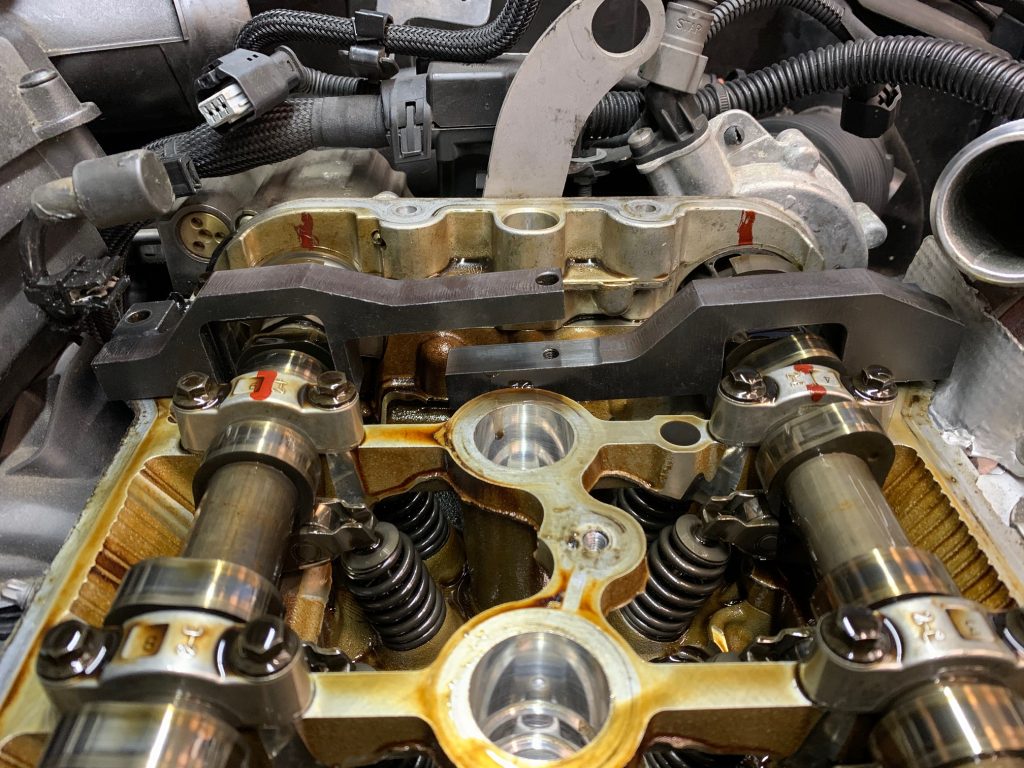

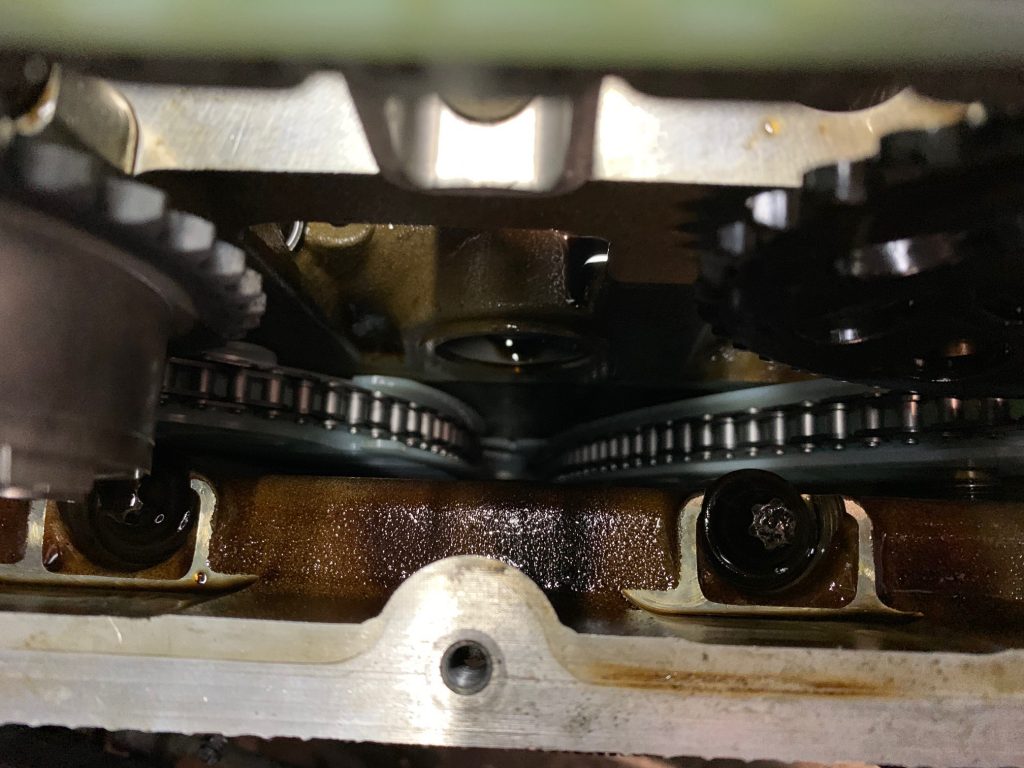

However, with all moving parts, especially ones under stress they wear causing noises, vibrations and lastly drive line failure! This was a Dual Mass Flywheel we replaced recently on a Citroen C5, as you can see from the pictures when the old Flywheel had failed it was allowing the clutch to sit off centre causing vibrations. Once the new Flywheel and Clutch Kit were fitted it sat central again.

This was a Dual Mass Flywheel we replaced recently on a Citroen C5, as you can see from the pictures when the old Flywheel had failed it was allowing the clutch to sit off centre causing vibrations. Once the new Flywheel and Clutch Kit were fitted it sat central again.