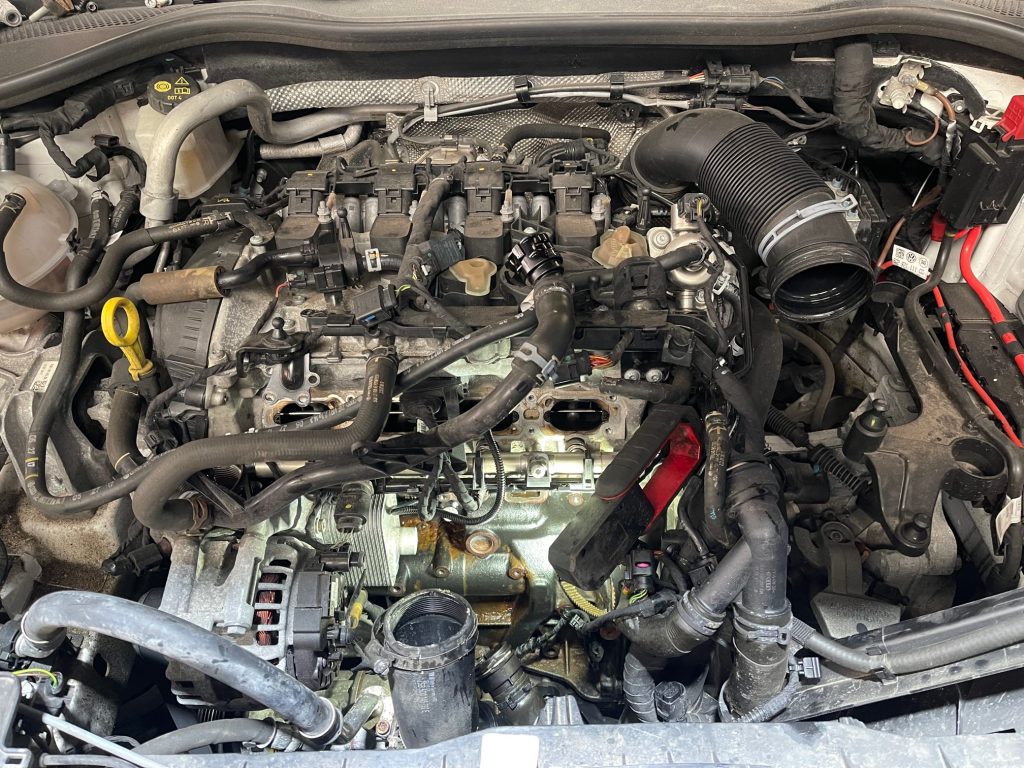

This Ford Transit came into us with its Engine Management Light (EML) on and running in Limp Mode, after a quick diagnostic plug in we could see that the DPF soot content was well over 100% and it was unable to carry out a dynamic regeneration.

Vehicles with DPF’s require a long run at least once a fortnight to allow for a Dynamic Regeneration of the DPF.

We cleared the codes and attempted to carry out a static regeneration of the DPF which again was unsuccessful.

By monitoring the voltage of the exhaust temperature sensors we could see there was no change during the whole procedure and the exhaust temperature didn’t go above 170 degrees.

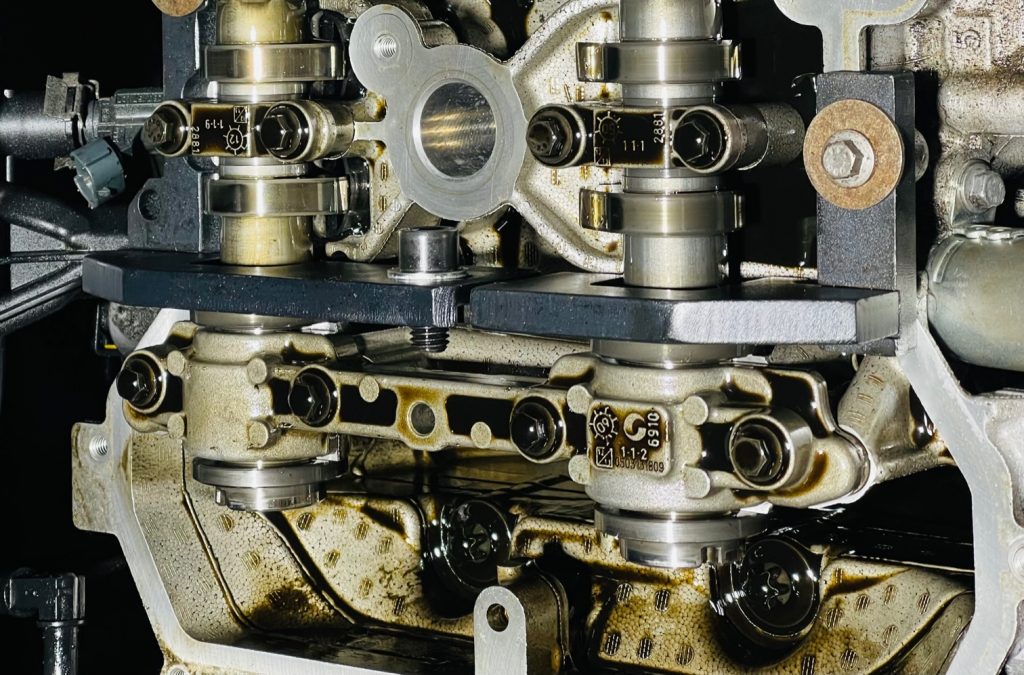

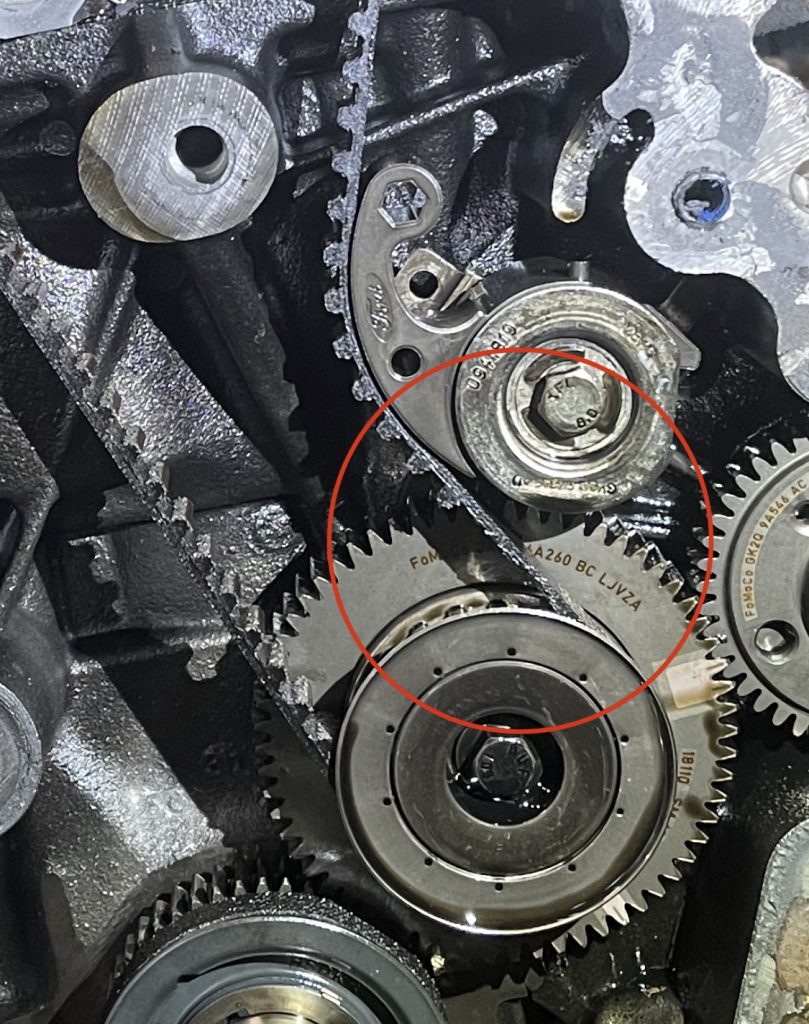

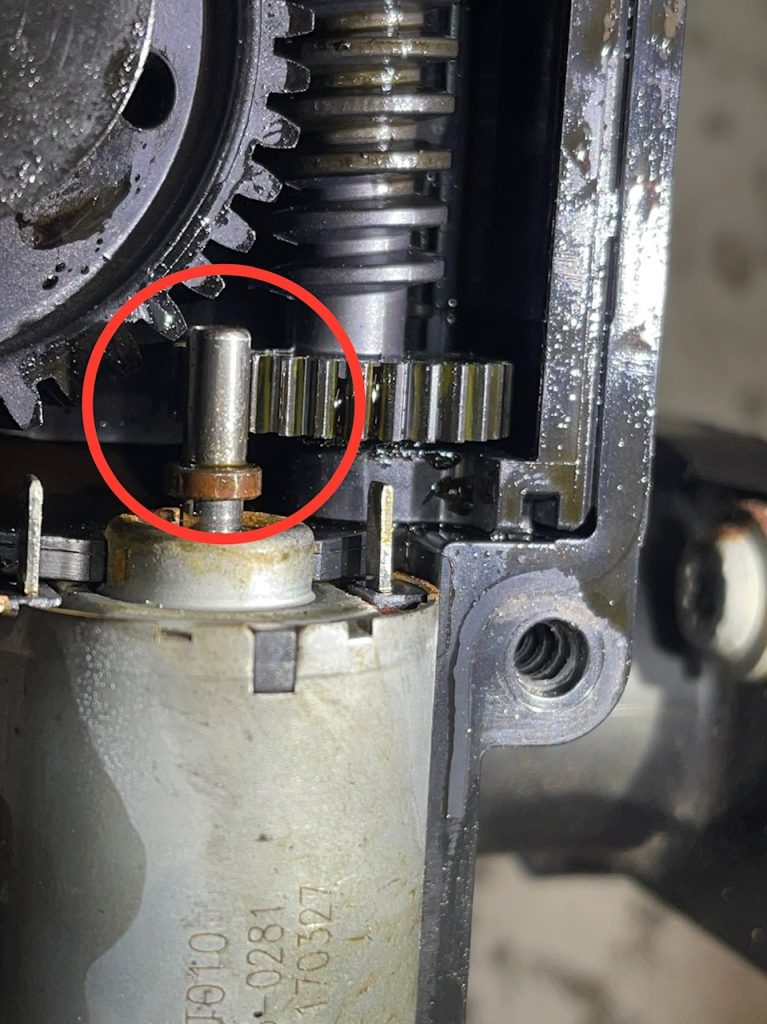

The first thing to check at this point is the Diesel Vaporizer which is located in the exhaust front pipe (normally seized).

Once we had removed the Vaporizer it was obviously blocked (see video).

We cleaned the Vaporizer and made sure the feed pipe wasn’t blocked and also checked the heater element was working by spraying WD40 into the Vaporizer and powering up the heater element with a 12v power probe, the WD40 should start to mist out of the little hole.

Next we refitted the Vaporizer and attempted the static regeneration again.

Success, the voltage of the temperature sensors dropped and the DPF temperature went up to over 600 degrees and you could smell the soot and carbon being burnt out of the DPF.

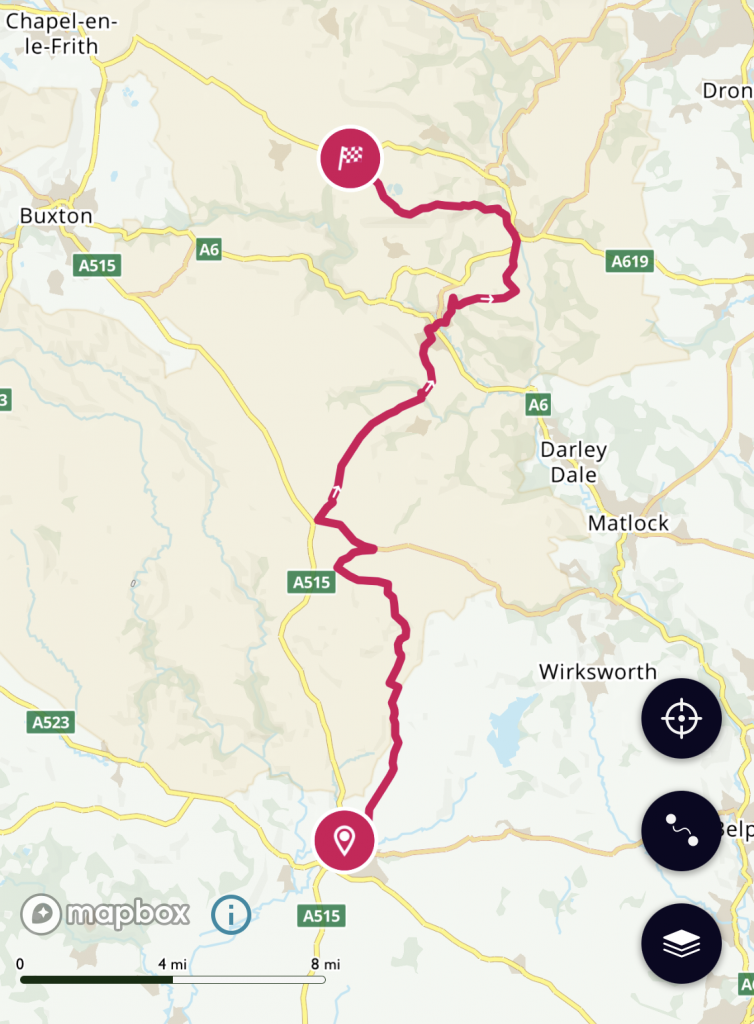

Lastly was a long road test to make sure it didn’t go back into Limp Mode and no codes returned.

Your friendly car garage in Derby

Give us a call at Aarons Autos for more info.